Ball Mills 2c High Capacity

Ball Grinding Mill Sizes And Capacities

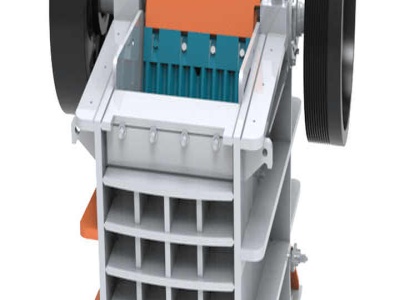

Ball Mill Parameter Selection amp Calculation. Aug 30 2019 1 calculation of ball mill capacity the production capacity of the ball mill is determined by the amount of material required to be ground and it must have a certain margin when designing and selecting there are many factors affecting the production capacity of the ball mill in addition to the nature of the material grain size hardness ...

capacities of ball mill

Ball mill 50 tph capacity henan mining machinery .05 to 50 tph industrial ball to 50 tph industrial ball mills ball mill capacity table steel head ballrod mill the steel head ballrod mill gives the ore dressing engineer a wide choice in grinding design so that he can easily secure a ballrod mill suited to his particular problem the successful operation of any grinding unit.

ball mill kbm 2c

mill grates, thus enabling longlasting full mill capacity Low operating costs Low initial costs Selfsupporting structure Standard range drive parts One feed point in low position Flexible and versatile Adaptable to All cement grinding ball mill systems Fully .

Ball Mills Capacities And Reduction Ratios

Ball Mills Capacities And Reduction Ratios Ball Mill Design Power Calculation Mineral Processing . The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating solids or pulp density, feed .

capacities and specifiions vibrating ball mill

ball mill specifiions power capacity weight motor speed ball mill specifiions power capacity weight motor speed. STEEL BALL MILLS PEBBLE MILLS food processing equipment ball mill specifiions power capacity weight motor speed,shows typical paste charges based on 33 1/3% ball charge and mill speed at 50% With these conditions, paste capacity can range from a low of 14% to a high .

capacities of ball mill in mongolia

capacities of ball mill in mongolia. Capacity 0187 m ³min Suitable Materials Limonite OreCopper zinc lead nickel gold and other nonferrous metals ferrous and nonmetal Major Equipment Jaw crusher ball mill sprial classifier magnetic separator concentrator machine and dryer machine Read More...As a leading global manufacturer of crushing equipment, milling .

ball mill sizes and capacities

Ball Mills. Ball mills designed for long life and minimum maintenance overflow ball mill sizes range from 5 ft x 8 ft with 75 HP to 30' x 41' and as much as 30,000 HP Larger ball mills are available with dual pinion or ring motor driv Our mills incorporate many of the qualities which have made the Marcy name famous since 1913.

Ball Mills

· Grate Discharge Ball Mill: This type of mill usually works with a high circulating load and thus produces very little extreme fines. The specific power consumption is therefore less than for an Overflow Mill. A Grate Discharge Mill will also have 15—25 % higher capacity per volume unit as compared with an Overflow Mill.

ECOMAX MAGOTTEAUX GROUP THE GLOBAL SOLUTION .

Ecomax® Forged balls are manufactured from high quality steel bars and then forged into balls. They are submitted to tailored heat treatments in order to obtain the required structure and properties. Ecomax® Forged is suitable for ball milling and ... WITH A GLOBAL CAPACITY IN EXCESS OF 415,000 TONS PER YEAR.

Ball Mill

The High Energy Ball Mill Emax and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming effects. These ball mills are also suitable for mechano chemistry.

ball mills 2c ball mills

Industrial Ball Mills Steel Ball Mills and Lined Ball. Ball Mills Our combined experience in ball mill design and process equipment development totals more than 60 years and allows us to put a unique spin on steel and lined mills Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800's

Molinosde Balls For Mineral Capacities And Sizes

Molinosde Balls For Mineral Capacities And Sizes. piedra molinos de bangladesh sand making ball mill HFC Refrigerants 55 HST Hydraulic Cone CrusherHST series hydraulic cone crusher is combined with technology such as machinery hydraulic pressure electricity automation intelligent control etc representing the most advanced crusher technology in the world

capacities of ball mills

capacities of ball mills. Calculate Ball Mill Grinding Capacity,Oct 15 2015 · The sizing of ball mills and ball milling circuits from laboratory grinding tests is largely a question of applying empirical equations or factors based on accumulated experience Different manufacturers use different methods and it is difficult to check the validity of the sizing estimates when estimates from ...

Ball Milling 2c Manufacturers

Laboratory Ball Mill 5 Kg 10 Kg Capacity Ball Mill ... Bionics Scientific is a leading laboratory ball mill manufacturer in India and offers its customers a fair deal in buying ball mills with facilities of customized ... rock crushing hammer mill 2c india

Capacities Of Ball Mill

Capacities Of Ball Mill. Ball Mill Parameter Selection Calculation Power. 1 Calculation of ball mill capacity The production capacity of the ball mill is determined by the amount of material required to be ground and it must have a certain margin when designing and selecting There are many factors affecting the production capacity of the ball mill in addition to the nature of the material ...

ball mill specifiions 2c cylinder

Ball Mill Specifiions Cylinder. ball mill basic specifiions helinbud The basic types of commonly used ball mill in the production are grate mill overflow ball ball mill is 10 15 higher than overflow type ball mill with the same specifiions an Chat Online ball mill is a research project which is depended on material to be mill . Chat Online

cement grinding mills of capacities and prices

Comparing ball mills and VRMS for cement grinding ... tackles the question of ball mills vs VRMs for cement grinding. ... in cement grinding – a high capacity VRM that would replace two or three cement mills.

Planetary Mills –

Planetary Mills are ideally suited for fine grinding of hard, mediumhard, soft, brittle, tough and moist materials. The comminution of the material to be ground takes place primarily through the highenergy impact of grinding balls in rotating grinding bowls.

ball mills 2c high capacity

ball mills 2c high capacity. Mill (grinding)Wikipedia. Rod mills are less common than ball mills for grinding minerals. The rods used in the mill usually a highcarbon steel can vary in both the length and the diameter. However the smaller the rods the larger is the total surface area.

Latest Posts

- بازار كسارة الفلفل الكبير

- الجزء الأسطواني محطم في الجزائر

- الموردين صخرة الحجر في المملكة العربية السعودية

- تستخدم مصنع إثراء خام الحديد للبيع

- مصنع معالجة خام الحديد في مصر

- مصنع كسارة الحجر 500 tph الصين

- الإجراء العملي لسحق الخبث في صليب الفك

- كسارة الحجارة مستعملة للبيع في أوروبا

- كسارات دلهي مصر

- حجر صخرة نهر في اليمن

- آلة يدوية نحاسية لفافة صنفرة

- محجر تعدين الجبس في بورا

- الشركة المصنعة لآلات المحاجر في عمان

- كسارة التعدين البازلت الفلسبار

- سحق مصنع الحجر الجيري الاستثمار

- Used Concrete Plant For Sale In Brazil

- Spiral Concentrator Helix

- Best Mexico Jaw Mexico

- Biggest Biggest Mining Companies In Usa

- Clutch Grinder Go Kart

- Belt Sri Lanka For Coal Sri Lanka In Sri Lanka

- Http Mail Mining Itb Ac Id

- Mini Ball Mill Project In Chile Pdf

- Slate Mines Introduction In Dominica

- Quarry Russia Stone In Russia

- Iron Ore Benification Plant Animated

- Rotary Mongolia Mongolia Granite

- Mexico Beneficiation Process For Sale

- Rule Of Mining Department For Stone Russia

- Chilli Grinding Machine Manufacturers In Portugal